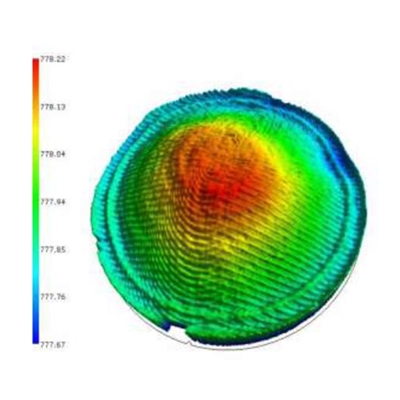

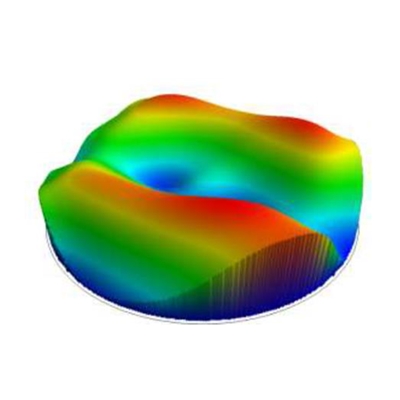

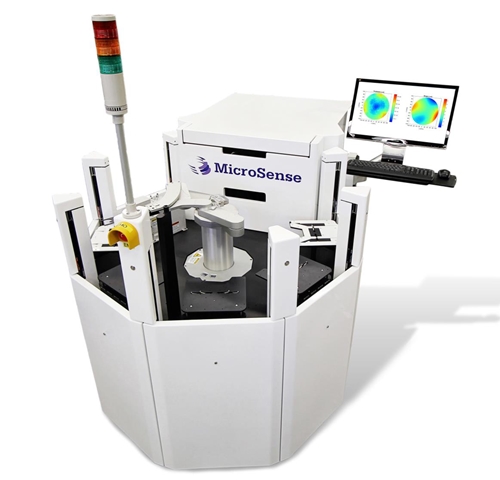

MicroSense capacitance sensor based metrology systems perform full wafer mapping,

generating high resolution geometry data for each wafer.

Wafer metrics

include thickness, flatness, bow and warp.

| Application | Thickness, Flatness, Shape | Stress | Backgrind Thickness |

|---|---|---|---|

UMA-C200L(200mm bare silicon wafers) |

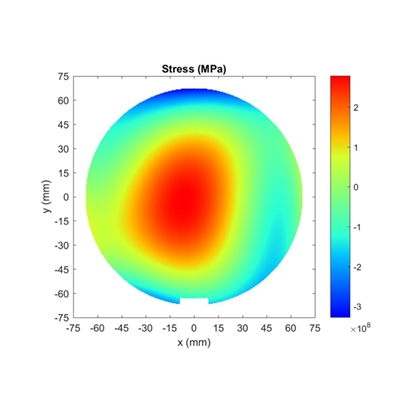

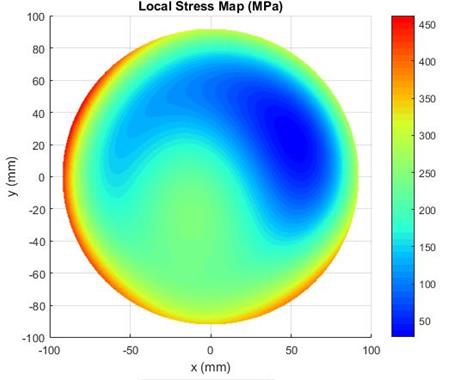

UMA-C200-STR(150/200mm silicon full wafer stress) |

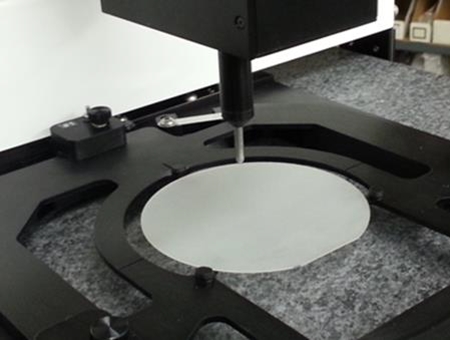

UMA-200-BP(150/200mm thinned back grind wafers, material independent) |

|

| Market | Bare Wafer Manufacturing | Device Manufacturing - Front End | Device Manufacturing - Back End |

| Application | Semi-auto benchtop | Manual benchtop | |

|---|---|---|---|

UMS-C200B(100/150/200mm silicon, SiC, sapphire) |

UMS-200-BPBT(100/150/200mm thinned back grind wafers, material independent) |

UMM-BP1V-X30(Up to 300mm, thinned back grind wafer) |

|

| Market | Development & Low Volume | Thinned wafer on film, Saw frame | |